Tiger’s eye is found in many countries, such as South Africa, Australia, and the United States. It comes from a process called pseudomorphism, when blue asbestos turns into quartz under the right conditions.

People have been taking tiger’s eye out of the ground for centuries, but it’s said that commercial mines opened in the late 19th and early 20th centuries when the stone became very popular.

Let’s take a closer look at where most tiger’s eye is found, what special conditions were necessary for tiger’s eye deposits to form there, and how tiger’s eye is mined today.

In this blog post, you’ll discover:

- Where tiger’s eye comes from

- How tiger’s eye is formed

- And how tiger’s eye is mined

Where tiger’s eye comes from

Tiger’s eye is a stone that’s found in many countries across the world, but most tiger’s eye is mined in these five countries:

South Africa

The Northern Cape province of South Africa is a source of high-quality tiger’s eye, particularly in a town called Griquatown.

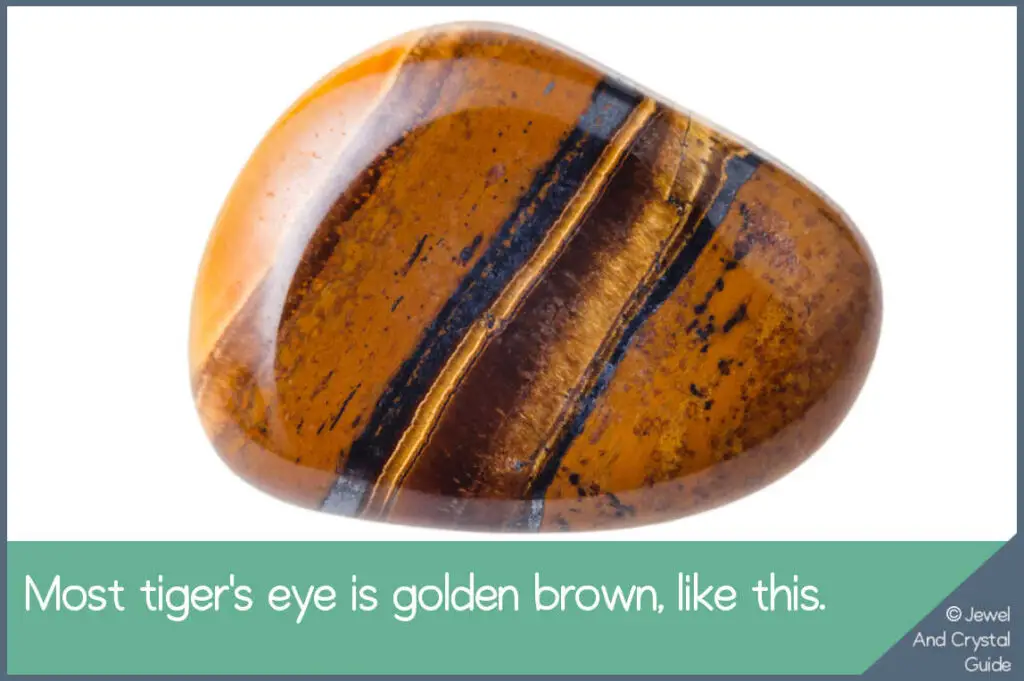

Tiger’s eye from this region is well-known for its distinct golden-brown color and fine chatoyancy. Most red tiger’s eye comes from South Africa, but blue, green, and black tiger’s eye are also found in South Africa.

You can read more about the different types of tiger’s eye in this blog post.

Chatoyancy is the cat’s eye effect in tiger’s eye: Just as light reflects off a cat’s eye at night, so does light reflect off a tiger’s eye crystal. The reflection from the crystal looks a lot like a cat’s eye, and is one of the reasons why it’s called “tiger’s eye”.

Click here to find out all the reasons why tiger’s eye shines the way it does.

Australia

Western Australia, particularly the regions of Pilbara and Kimberley, is known for its tiger’s eye.

Australian tiger’s eye is golden brown or a unique blue-gray color.

United States

Tiger’s eye is found in several U.S. states, including California, Arizona, and South Carolina.

Genuine American tiger’s eye is typically known for its rich golden-brown color and shimmering chatoyancy.

India

Some tiger’s eye is mined in India.

Indian tiger’s eye has a deep golden-brown color and strong chatoyancy.

Brazil

Brazil is also a source of tiger’s eye, particularly from the state of Minas Gerais.

Brazilian tiger’s eye is golden-brown and chatoyant.

How tiger’s eye forms

Natural tiger’s eye forms over millions of years under the right conditions.

Tiger’s eye is created when a mineral called crocidolite is turned into quartz, in a process called pseudomorphism. Crocidolite is a fibrous blue mineral that’s also known as blue asbestos.

There are three things that must be present or happen for tiger’s eye to form in an area:

- Crocidolite must be in the area to begin with. The more crocidolite, the more tiger’s eye can form there.

- Then iron and silica must come into the area, usually in a hot liquid. These elements are important because quartz is made of them.

- Then other conditions need to happen, such as intense heat and pressure on the right kinds of rocks, before we get a deposit of tiger’s eye over a few million years.

How tiger’s eye is mined

Tiger’s eye is typically mined using conventional mining methods, such as open-pit mining or underground mining, depending on the location and deposit characteristics.

The specific mining process depends on the geological conditions and size of the deposit, but generally includes the following steps:

Exploration and site preparation

Geologists and mining engineers identify potential tiger’s eye deposits through geological surveys, mapping, and sampling.

Once a viable deposit is identified, the mining site is prepared by clearing vegetation, removing overburden (rock or soil covering the deposit), and establishing access roads and infrastructure.

Extraction

In open-pit mining, large equipment, such as bulldozers and excavators, are used to remove the overburden and extract the tiger’s eye-bearing rock or mineralized material.

In underground mining, tunnels are excavated to access the deposit, and the tiger’s eye-bearing rock is extracted using drills, explosives, and other mining equipment.

Sorting and processing

After extraction, the tiger’s eye-bearing rock is transported to a processing plant, where it is sorted, crushed, and screened to separate the tiger’s eye from other materials.

Raw tiger’s eye may be sold as is or processed, where it is grinded, cut, and/or polished to shine.